Szentgotthárd: the Allison Transmission European production site

With a strong customer base in the Old Continent, Allison installed its European HQ in the Netherlands, more precisely in Sliedrecht, a small town some 25 km south-east of Rotterdam, where we also find a Parts Distribution Center as well as technical training facility. But the operational site for Allison Transmissions in Europe is located in Hungary, at Szentgotthárd

Since October 2000 Allison Transmission started producing some of its transmissions in Europe, more precisely in the small Hungarian town of Szentgotthárd, around 15 km from the border with Austria and some 70 km east of Graz, a location where other automotive companies are based. In fact, the Allison facility is located where a former Opel site was based. The first transmissions that left the Hungarian plant were 3000 Series and Torqmatic, while in August 2005 the 4000 Series was added, the facility reaching the 100,000 systems produced by April 2008.

Allison Transmission decided to invest in its Hungarian facility, and on April 22nd, 2011, eight months after the work was started, the new manufacturing facility was ready, becoming operational five weeks later. The Hungarian facility covers an over 106,071 m2 area the production building has a surface of 13,200 m2. The new building was dedicated on October 4th, and shortly after the Customization Center became operational. This was a key element in the production process; before this, standard transmissions were assembled in Hungary, those needing customisation being sent to the Netherlands to be customised and then delivered to customers, the full process being now done in Szentgotthárd with considerable cost and time saving.

“The request for customisation is increasing,” Péter Rezsnyák, the Area Manager of the Allison Transmission Hungary plant at Szentgotthárd explained; “in the past around 60% of our production had to go through the process, but now we have reached 75%,” he explained, a much higher percentage compared to that of US production lines.

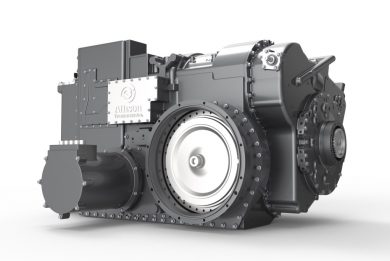

Four types of transmissions are manufactured in Szentgotthárd, the TerraTran for offroad heavy duty vehicles having been added in December 2021, however only the 3000 and 4000 Series are used for military wheeled vehicles. The 3000 has up to 6 speeds, can accept a gross input power of 336 kW and a gross input torque of up to 1,695 Nm. Its mass is between 243 and 297 kg, depending on configuration, and can be fitted with an integral retarded and up to two Power Take Off (PTO). For the 4000 Series with 6 speeds the data increase to 485 kW, 2,644 Nm, 377-439 kg, the same options being provided. A 7-speed version of the 4000 Series can accept 597 kW, 2,644 Nm and has a mass of 555 kg, 4000 Series transmission having the same key options of the 3000.

“Considering the different customisation requirements, over 300 different types of 3000/4000 Series transmissions leave our plant,” Péter Rezsnyák underlines. The Hungarian facility produces transmissions with components coming mostly from the United States, around 70%, the remaining being provided by the company European supply chain, no machining being done in Szentgotthárd. According to the manager the assembly of a standard transmission requires around 2.8 hours; the U-shaped 110 meters long assembly line is made of 10 main stations located along a conveyor that ensures the movement of the assembly from one station to the next. Alongside the outer part of the “U” we find sub-stations were components and sub-assemblies relevant to the operation to be carried out along the line are pre-assembled or stored; clutches, supports, covers, torque converters, planetaries, up to the rear module and the cooler, which are the last element to be assembled. Most of the assembly stations have two such sub-stations alongside, as the single line produces either the 3000 Series or the 4000 Series depending on the day, currently Tuesday and Thursday being dedicated to the 4000 Series production.

While quality assurance is provided at each station, with over 240 error proofing points along the line, all connected to the line control system. Once assembled the transmission is submitted to a series of tests on six further stations. In the functional test the system is filled with the right amount of oil, 22-23 litres for the 3000 Series and 42 litres for the 7-clutch 4000 Series, and the transmission is run at different speed and gears are automatically shifted, while oil pressure is measured. It is then emptied and submitted to the leak test, where it is kept in a water basin with an inside 0.5 bar overpressure to see if any bubble appears showing unwanted porosity. The transmission is kept in position for 30 seconds, then turned and kept for 30 more seconds. The transmission is then dried with pressure air before going to a station where rust protection is applied, before installing the cooler.

After tests have been performed, those transmissions that need customisation go to the MOD Centre”, for modification, where eight assembly stations run each by one experienced operator receive the standard transmission which is customised according to customer’s needs. This operation can last from 15 minutes to over 2 hours.

A Tear Down Audit is performed for each shift; one transmission is selected among those produced and undergoes an audit test. It is fully disassembled checking all torque values etc, to detect any quality risk. Should a problem arise, the two serial numbers before and after the one that has gone through the test are also disassembled, and if results are not satisfactory the 10 before and after the teste one go through the same process, until the quality manager is not satisfied. Usually no problems arise, therefore the unit is reassembled, replacing some gaskets. According to Mr. Rezsnyák quality issue at this stage happen 2-3 times per year. Only when the audit test is satisfactory, the production of that shift is cleared for shipping.

The final assembly operation is the calibration of the Transmission Control Module; before being fitted to the transmission the TCM is loaded with the calibrated data package, based on customer’s demand, coming directly from Indianapolis. This is the only part of the facility where we find female personnel, as the assembly of mechanical parts requires efforts that do not allow to employ women.

From here the transmissions are transferred to the packaging area, where they are fitted into containers, some customers requiring boxes with specific characteristics, Japan pallets being for example smaller than European ones.

Production is currently running on two shifts per day five days per week; EDR On-Line understood that the morning shift is manned at 100%, which means around 42 personnel, while the afternoon one is manned at 60%. With this configuration, between 104 and 106 transmissions are assembled every working day by personnel who is trained on both types of transmissions and can therefore switch from one to the other without any problem. The target production for 2024 is 24,000 transmissions, the average output of the Szentgotthárd facility being nearly 10% of the overall Allison overall production, including that of the Indian factory which produces 1000 Series system. Should the market require a higher output, the production rate could be increased by fully manning three shifts, bringing the annual production at around 36,000 pieces.

As seen, the assembly line is mostly manual; the numbers do not justify a fully robotised line, which would also be much less flexible in terms of production.

The transmissions produced in the Szentgotthárd facility are mostly aimed at the European market, however among the Hungarian site customers we also find OEMs in the Middle East and Africa, in Japan, as well as in China, the latter obviously for non-military products. No information was provided on the split between transmissions aimed at the commercial and military markets.

Photos by P. Valpolini